Packaging involves more than just wrapping a product efficiently. It has become a part of the overall product experience. Modern day customers give high importance to packaging while purchasing a product. It would not be wrong to say that the value of a product is gauged by the quality of its packaging. With the growing awareness about sustainability and need for effective branding, businesses must pay attention to their packaging and printing style. To ensure efficiency, it is necessary to make use of smart technology, including the use of a bag making machine. The latest packaging and printing machines have been designed to meet the modern packaging requirements. In this article, we have shared details about the different types of machines businesses are using to fulfill these needs. Read on to find out!

To improve efficiency, businesses are increasingly turning to a bag making machine for their packaging needs.

The Increasing Demand for Packaging and Printing in 2025

The demand for packaging and printing has grown over the years. This is mainly because of the growing craze for online shopping. Every product, big or small, needs proper packaging and labeling. Customers, these days, give weightage to the look and feel of a package when it reaches them. Thus, brands are leveraging packaging to build trust and share their story.

The trend is evident as companies invest in a bag making machine to enhance their packaging solutions.

The demand for eco-friendly packing options has witnessed a rise. Paper and non-woven bags are slowly replacing plastic ones. Businesses need machines that can handle paper, fabric and other recyclable materials. Many small brands are investing in printed packaging to stand out. Custom printing has become common even for short runs. Speed, cost and design quality matter more than ever. Companies are also looking for machines that save energy and reduce waste. All of this is pushing the industry to upgrade its machines and processes.

Innovations in a bag making machine technology are driven by the demand for better packaging options.

Top Packaging and Printing Machines in 2025

Many types of machines are helping businesses meet the growing printing and packaging demand. Let’s look at the top ones in the market:

1. Paper Carry Bag Making Machines

These machines are used for making sturdy paper bags. They are commonly used at grocery stores, food outlets and gift shops. The newer models can make several paper bags in one minute. Some machines also come with printing units. This allows brands to print their logos on the bags directly. Handle pasting and folding are done smoothly using relevant features on this machine. These machines are fast and easy to operate. They help small businesses produce neat, branded bags in less time.

Using a bag making machine allows businesses to streamline their production and cater to customer preferences.

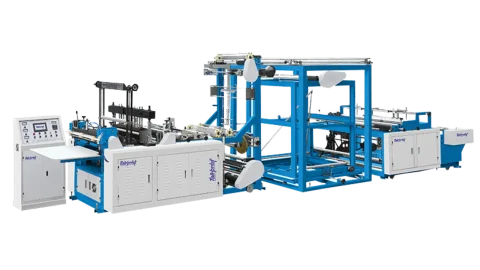

2. Non-Woven Bag Making Machines

Non-woven bags are strong, light and reusable. These machines create bags from spun-bond non-woven fabric. They can make various types like D-cut, loop handle and box bags. Ultrasonic sealing gives a clean and strong finish. The machines work well for bulk production and are energy efficient. Most of them also have touch panels for easy settings. Many businesses use these machines to make custom printed reusable bags.

With a bag making machine, businesses can efficiently produce reusable bags tailored to their branding.

3. Mini Offset Printing Machines

These machines are ideal for small print jobs. They work well for paper, cardboard and even non-woven materials. Businesses use them for printing brochures, paper bags and covers. Mini offset machines are compact and don’t need much space. Newer models offer better colour quality and quick plate changes. This makes them great for short-run printing. They help local printers and small businesses keep up with fast orders.

A bag making machine simplifies the printing process, ensuring vibrant designs on packaging materials.

4.Square Bottom Paper Bag Making Machines

These machines produce square bottom paper bags. The bags are stable and hold more weight. They are often used by grocery stores, bakeries and cafes. The machines offer smooth folding and gluing. Some models also come with inline printing options. They use water-based glue, which is better for the environment. These bags look neat and are easy to stack. Many eco-friendly brands prefer this style.

Brands often choose a bag making machine for its ability to produce environmentally friendly packaging.

5. V Bottom Paper Bag Making Machines

V bottom bags are common in pharmacies and snack shops. These machines are fast and suitable for large quantities. They can adjust for different paper types and sizes. The machines are quiet and don’t use much power. Some versions also have basic printing attachments. This makes them great for simple packaging with a name or logo. They help businesses produce bags quickly without spending much.

Investing in a bag making machine is essential for businesses looking to meet modern packaging challenges.

6. Flexographic Printing Machines

Flexo printing machines are used for printing on many surfaces. They work with paper, plastic film and non-woven fabric. These machines are used for labels, food wrappers and shopping bags. They support two-colour, four-colour, and even eight-colour printing. The latest machines come with ink-saving features and quick dryers. They also have camera systems to check print quality. Flexo machines are fast and suitable for long runs.

Flexographic printing combined with a bag making machine enhances customization options for packaging.

7. Single Colour Poly Offset Printing Machines

These machines print on plastic sheets like LDPE and HDPE. They are used for courier bags and packing covers. They offer sharp, single-colour prints and are easy to use. Corona treatment helps the ink stick better to plastic. These machines are popular in courier and packaging businesses.

For couriers, a bag making machine is invaluable in producing durable packing solutions.

8. Double Colour Poly Offset Printing Machines

These are similar to the single-colour versions but offer more colour options. They print with two colours for better design. The machines work on plastic films used in courier bags. They offer proper alignment between both colours. Newer models come with automatic cleaning and better speed. They also use less ink and power. Many online sellers and logistics companies use these machines for branding.

Using a bag making machine allows for quicker fulfillment of orders in the logistics industry.

Conclusion

Understanding the benefits of a bag making machine can drive innovation in packaging for many brands.

In 2025, packaging is more than just a way to wrap products. It plays a big role in how people see a brand. The demand for eco-friendly packaging is on a rise. Businesses are moving from plastic to paper and non-woven options. Thus, machines that support this shift are in high demand. With the use of the latest technology, bag making and printing machines offer quick output. Flexo and offset printing machines help even small companies look professional. These machines support the need for speed, quality as well as sustainability. As the market grows more competitive, the right machine can make a big difference. Whether you are a start-up or a growing business, investing in smart packaging tools is a smart move for 2025.

In conclusion, a bag making machine is crucial for businesses aiming to enhance their packaging strategy in 2025.