Your choice of printing technique for bags can significantly impact the overall appeal and success of your product. With a wide range of printing options available, selecting the right one is crucial for achieving the desired visual impact, durability, and cost-effectiveness. In this article, we will explore some of the best printing techniques for bags. You will learn about various machines used for printing purpose. This includes the mini offset printing machine, single pass digital printing machine, flexo printing machine, and non-woven printing machine. Understanding these printing methods will empower you to make informed decisions and ensure your bags stand out in a competitive market.

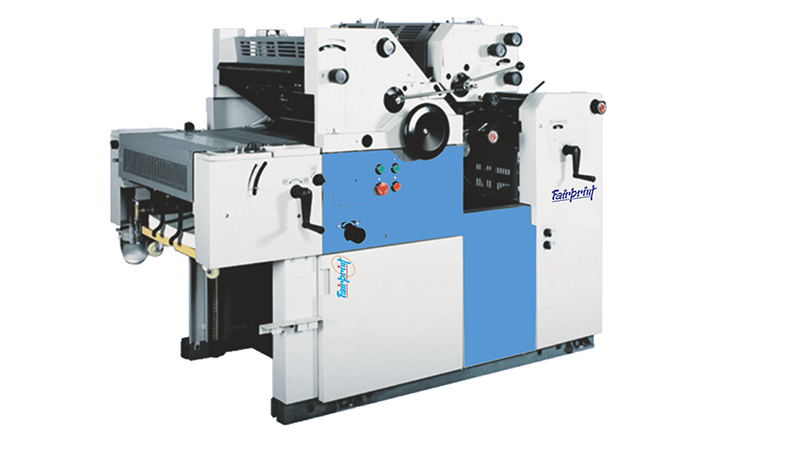

Mini Offset Printing Machine

Mini offset printing is a versatile and cost-effective technique. It has gained popularity for its ability to produce high-quality prints on various materials, including paper and cardboard. This printing method involves transferring ink from a plate to a rubber blanket before finally making contact with the bag material. One of the key advantages of this method is its capability to handle intricate designs with fine details. This makes it ideal for bags that require a sophisticated and professional appearance.

The precision and consistency offered by this printing technique makes it a top choice for businesses looking to maintain brand integrity across their product range. The affordability of mini offset printing machine, combined with its ability to handle small to medium print runs, makes it a practical choice.

Single Pass Digital Printing Machine

This machine has emerged as a revolutionary option for bag printing. The technique involves transferring digital images directly onto the bag material without the need for plates or screens. The process is swift, enabling high-speed production with minimal setup time. Single pass digital printing is particularly advantageous for short print runs. It eliminates the need for costly setup processes associated with traditional printing methods.

The flexibility of this technique allows for customization and personalization on a large scale. Brands can experiment with different designs, colours, and graphics without incurring substantial additional costs. This is especially beneficial for businesses that frequently update their branding or cater to niche markets with specific preferences.

Flexo Printing Machine

Flexography, commonly known as flexo printing, is a popular choice for printing on a wide range of materials. This includes plastic, paper, and non-woven fabrics. This method involves the use of flexible relief plates and fast-drying inks, making it a high-speed and cost-effective option for large-volume printing. Flexo printing is well-suited for bags with simple and bold designs as it excels in reproducing solid colours and simple graphics.

A notable advantage of flexo printing is its ability to produce vibrant and consistent colours across a variety of substrates. This makes it an excellent choice for brands that prioritize colour accuracy and visual impact. Moreover, flexo printing machines are versatile and can be adapted for both online and offline printing processes. It provides businesses with flexibility in their production workflows.

Non-Woven Printing Machine

Non-woven bags have gained popularity as an eco-friendly alternative to traditional plastic bags. Printing on non-woven materials requires specialized equipment, such as the non-woven printing machine. This printing technique is designed to handle the unique characteristics of non-woven fabrics to ensure durability and longevity of the printed design.

Non-woven printing machines use methods like screen printing or flexography to transfer ink onto the non-woven material. The result is a crisp and vibrant print that withstands the wear and tear associated with reusable bags. Brands aiming to convey a commitment to sustainability and environmental consciousness often opt for non-woven bags. High-quality prints are achieved through these specialized printing machines.

Choosing the Right Printing Technique

Choosing the right printing technique for your bags depends on a variety of factors. This includes your budget, the desired print quality, the volume of production, and the material of the bags. Here are some considerations to help you make an informed decision:

1. Budget

If you are working with a limited budget and require high-quality prints for small to medium runs, the mini offset printing may be the most cost-effective option.

2. Volume of Production

For large-scale production with consistent and vibrant colours, the flexo printing machine is a suitable choice. Single pass digital printing machines are ideal for short print runs and customizable designs.

3. Material of the Bags

Non-woven bags demand specialized printing techniques to ensure longevity and colour retention, making the non-woven printing machine the preferred option.

4. Design Complexity

Mini offset printing excels in handling intricate designs with fine details. On the other hand, flexo printing is well-suited for simple and bold designs. Single pass digital printing offers flexibility for detailed and customizable designs.

Conclusion

The choice of printing technique for your bags can significantly impact your brand’s image and success. Understanding the strengths and considerations of different printing techniques empowers you to choose the right one as per your needs and goals. By choosing the right technique, you can ensure that your bags not only look appealing but also convey the essence of your brand to your target audience.